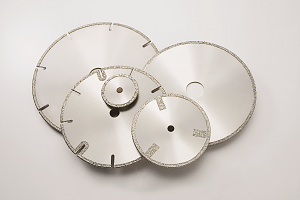

For many diamond tools an electroplating process is used to adhere a mono-layer of diamond grit to a metal tool. The process is used for many NIABRAZE products including diamond circular saw blades.

Understanding the Electroplating Process

The basic process of electroplating diamond grit to a tool revolves around two concepts: the anode and the cathode. During the electroplating process, a metal plating material is designated as the anode and will be plated onto the tool, which is designated as the cathode. Both the anode and the cathode are submerged into an electrolyte solution that contains metal salts and ions.

To begin plating, an electrical DC circuit is created which travels through the anode, through the solution, through the cathode, and back to the power source. When current is applied to the anode metal ions to dissolve into the electrolytic solution. The metal ions are then transferred by electrical current through the solution, and eventually deposited onto the cathode (tool) where they are plated onto the tool.

To begin plating, an electrical DC circuit is created which travels through the anode, through the solution, through the cathode, and back to the power source. When current is applied to the anode metal ions to dissolve into the electrolytic solution. The metal ions are then transferred by electrical current through the solution, and eventually deposited onto the cathode (tool) where they are plated onto the tool.

In the process of electroplating a diamond tool, several steps may be used. First the tool must be prepared for plating. Any areas of the tool that do not need to be plated will be blocked or masked using tape, way, or a special paint to protect from plating. Next the tool may be placed into a cleaning bath to remove an impurities that could compromise the plating efficiency or adhesion. Next an metal "strike" step may be used. A "strike" or "flash" coating is a thin metal later that primes the part for future plating steps. This thin coating ensure strong adhesion and efficient plating. In the following plating cycles, metal ions are deposited onto the tools to form a strong bond. During the plating cycles, diamond particles are distributed on the part and are encapsulated by metal ions. This forms a strong bond which secures the diamonds to the tool surface.

NIABRAZE Electroplating

NIABRAZE has over 25 years of electroplating experience. Our experts have plated tools both large and small. Regardless of the shape or size NIABRAZE tools set the industry standard with superior diamond adhesion. Meaning increased tool life, and ideal cutting or grinding efficiency. If you have questions about electroplating, then please click here to request more information.